877-929-7665

THE THURSDAY POOLS TRIFECTA

Multiple layers of strength create an incredibly durable composite pool.

There’s nothing quite like a really great artisan-crafted sandwich, layered with quality ingredients. Every ingredient has a purpose and makes the end result better. It’s stacked just right from one end to the other. Sounds fabulous, right? You know what else is fabulous? A new fiberglass pool with a shell that’s hand-crafted like our sandwich example.

Let’s take a look at how we do it.

Gathering the best ingredients

Thursday Pools was one of the first ISO 9001-certified manufacturers in North America. This means we have completed a rigorous certification process in which we’ve agreed to meet strict international quality standards related to both raw materials and production methods.

Thursday Pools worked closely with the PINKTANK™ at Owens Corning to assess our pool shells’ structural needs. Their high-quality fiberglass is sourced exclusively in North America and undergoes rigorous quality assurance tests to comply with stringent ISO 9001 manufacturing standards.

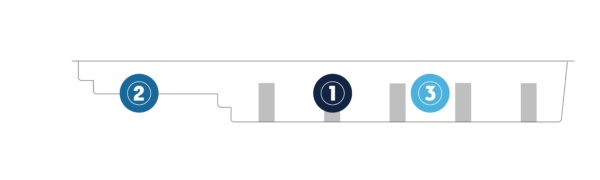

The 1-2-3 Trifecta of Strength

First, we create a mold to ensure consistent shape and dimensions. Once molded, a pool visits the gel station, where the top gel coat of the pool’s surface is applied. During this process, we constantly check the gel coat’s thickness to ensure it meets our high-quality standards. Once the gel coat is complete, a vinyl ester barrier coat is applied.

Next, we begin applying layers of strength. Between the honeycomb core of tubular supports and the outermost surface’s high-quality gel coat, every part of each pool by Thursday Pools features multiple layers of strength, including a combination of chopped fiberglass, hand-laid woven roving fiberglass, and a vinyl ester resin barrier coat.

Some higher stress points require more layers than others. We’ve assessed precisely how many layers of strength are needed at each point of the pool, formulating three laminate schedules to efficiently build pools according to each area’s structural needs.

Schedule 1, which consists of nine layers, is used for all horizontal surfaces above the floor. ISchedule 1, which consists of nine layers, is used for all horizontal surfaces above the floor. It also reinforces the walls with 6-inch-wide, 3-foot-tall strips approximately every 2.5 feet around the pool.

Schedule 2, also nine layers, is used for all higher-stress areas. The corners of steps, swim outs, tanning ledges, sun shelves, and benches are all reinforced with custom stitch mats, while an 18-inch-wide strip of woven rolling fiberglass runs along the floor’s inside perimeter and up the wall for extra strength where the floor and walls meet.

Schedule 3 is eight layers and is used in all areas that don’t require extra reinforcement, such as the floor (except the inside perimeter) and between the 6-inch-wide vertical strips on the walls.

What does all this mean to pool buyers?

It means you can be sure of your investment. You can trust you’ll receive an artisan-crafted fiberglass pool and will spend many years creating lasting memories with friends and family.