877-929-7665

Fiberglass Pools by Thursday Pools

Are Made of People, Passion, and Partnerships.

People are the foundation.

Thursday Pools’ reputation rests on its people. While we do push the boundaries of innovation and technological creativity, it’s ultimately a hand-crafted product and a face-to-face business. The experience, pride in workmanship, respect for each other and the customer, and passion for innovation all converge in the process of taking raw materials and converting them into the centerpiece of the backyard of your dreams. Thursday Pools represents:

- Over 35 years of experience in the fiberglass industry.

- Employees who are dedicated to efficient and sustainable practices.

- Facilities that exceed EPA and OSHA standards.

- A workplace that is both ISO 9001 and ISO 14001 certified.

- A passion for excellence extending to every facet of the organization.

Thursday Pools’ 150,000-square-foot, climate-controlled, ultra-high-efficiency manufacturing and training facility is located in Fortville, Indiana.

Fiberglass pools are our passion.

Our people take pride and satisfaction in a job well done. Innovation and continuous improvements are constant threads in everything we do. We’re passionate about pools, so the details are super interesting to us. Do you want to know what goes into our fiberglass pools?

MOLD IT.

MAKE IT PERFECT.

MOLD IT.

MAKE IT PERFECT.

A fiberglass pool’s overall quality is directly related to the mold that is used to produce it. All our molds have a complete steel substructure, and our pools are produced in a hospital-like, clean environment. This ensures a spotless finish and that your pool is laser straight, solid and built to last.

THERE'S STRENGTH

IN THE LAYERS.

THERE'S STRENGTH

IN THE LAYERS.

We sometimes describe our fiberglass pool shell as a “trifecta of strength” made up of three schedules and multiple layers that maximize the durability of the entire structure. Based on the engineering results of a finite element analysis (FEA), we use a different schedule for certain areas in the pool shell because some higher-stress areas require more and different layers than others.

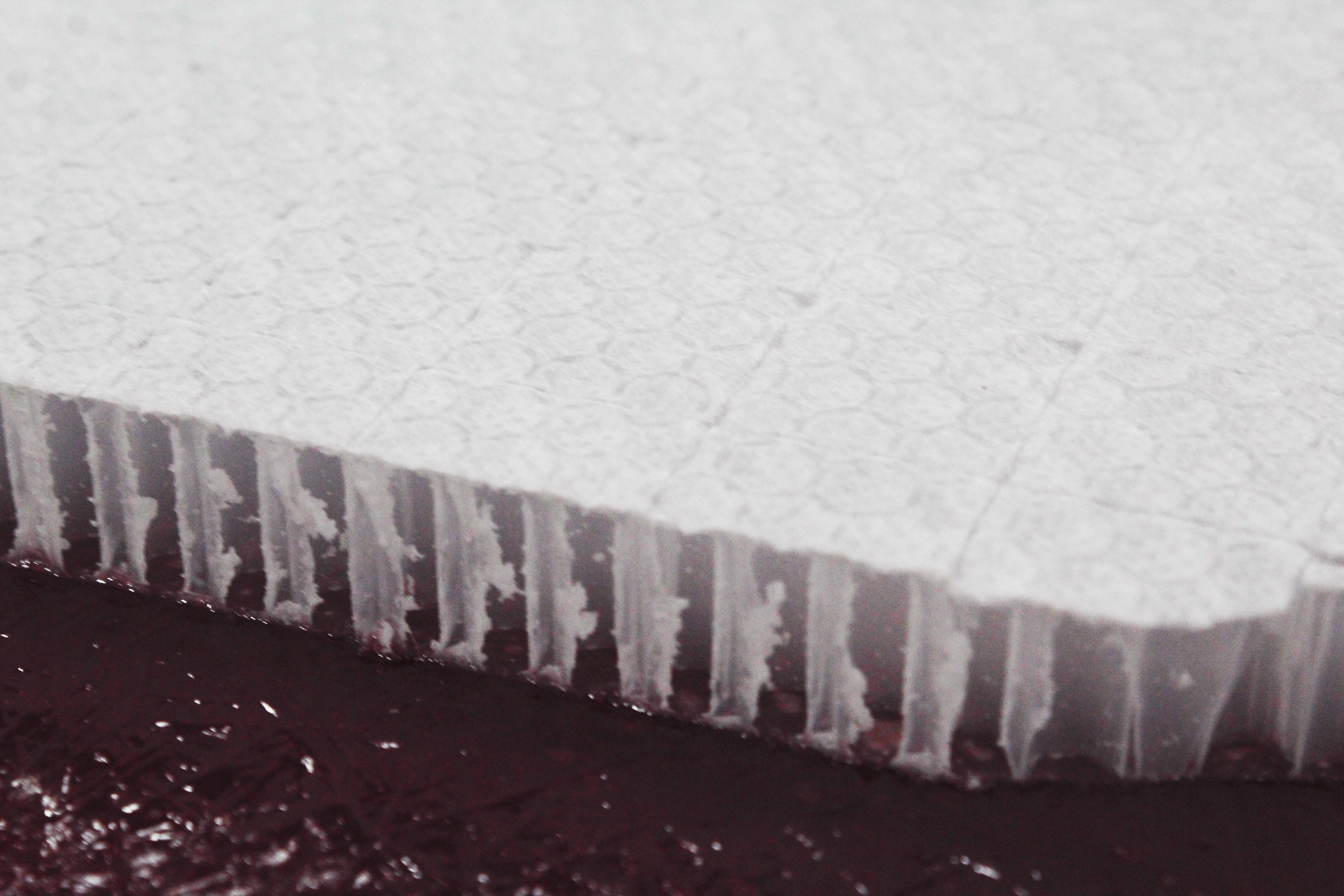

OH, SWEET HONEYCOMB CORE!

OH, SWEET HONEYCOMB CORE!

Thursday Pools adds vertical and horizontal supports throughout the pool by using a tubular construction method and a honeycomb core. This construction technique is applied to all horizontal surfaces such as steps, benches, and tanning ledges, as well as vertically, along the pool wall.

MORE FIBER IS GOOD FOR THE POOL’S DIET.

MORE FIBER IS GOOD FOR THE POOL’S DIET.

Fiberglass is combined with 100 percent resin and no fillers for several pool layers. Despite the cost and time involved, Thursday Pools uses both equipment-applied chopped fiberglass and hand-laid applied woven roving fiberglass to get the optimal physical properties that a best-in-class fiberglass pool requires.

TRUST US, VINYL ESTER IS A GOOD THING.

TRUST US, VINYL ESTER IS A GOOD THING.

Our vinyl ester barrier coat prevents potential blistering and protects the surface finish of your pool. We do not cut corners by adding fillers because adding any type of filler will decrease the structural properties and negatively affect the integrity of the surface.

SWEET GELLY! IT’S THE GEL COAT TO LOVE.

SWEET GELLY! IT’S THE GEL COAT TO LOVE.

Our pool surface gel coat is designed to last and look luxurious. It’s smooth, resistant to algae, and a dog’s claws won’t leave scratches. Thursday Pools uses the highest quality gel coat available, so you can feel confident in your purchase, knowing your pool surface is one of the most tested and reputable on the market. market.

Strategic Partnerships

How do we build enduring structural features into our pools? Or achieve a smooth, non-slip surface that doesn’t scratch the skin or snag swimsuits? Much of our success comes from our experience and diligence in cultivating the best possible strategic partnerships across suppliers and allied industries. These partnerships allow us to build our pools using high-quality materials such as:

- Release agents and purging compounds that help us meet the quality standards we require for our molds.

- Multiple layers of high-quality unsaturated polyester and vinyl ester resins, gel coats, and colorants.

- A honeycomb core that provides greater structural strength with less weight.

- Top-of-the-line glass fiber technology that ensures every layer of fiberglass meets the requirements for a best-in-class structure.

We partner with the best. While it may cost a little more upfront, our experience affirms it is worth it in the long run. We prototype, we test, and we patent! Whether it’s our multiple layers of strength, innovative and custom-built skimmers, or our patented anchoring system, Thursday Pools’ engineers and partners are on a constant mission to innovate.

Get Started With These Tools

Pool Cost Calculator

Want to do a little more research of your own? Use our Pool Cost

Calculator to quickly walk through a series of click-to-answer questions that can help you see what pool costs look like.

Pool Selector Tool

Did you know there are different types of pools that are suitable for different conditions, budgets, needs and different end goals? Use our Pool Selector Tool to determine the pool that suits you best.